|

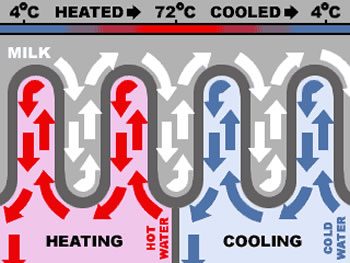

Our previous post, How to Choose Part 3, explored the difference between gravity fed and pump soft serve machines, and how these differences would affect your ability to provide what your particular operations require. Next we examine additional features that may be useful, or even mandatory in some instances. Chilled Hopper Machines Machines with hopper chilling capability have a setting that allows any left over material at the end of the day to remain in the hopper overnight instead of being drained and stored in the fridge. The hopper remains constantly chilled to around 4°C (standard fridge temperature). This allows any mixture to be safely left in the hopper for up to 5 days before it needs to be discarded and the machine cleaned. In practice most operations would have a continual throughput, with material only being left overnight, but you can see how useful this feature can be during slow periods, and how labour saving it can be.  Pasteurisation Cycle This is an automated feature where the machine performs a pasteurisation cycle overnight. Pasteurisation is a heat treating process that kills any pathogenic (disease causing) microorganisms in certain food groups. The material in the hopper and the barrel is heated to 71.7°C for 15 to 25 seconds, then cooled back down to 3-4 °C. Machine manufacturers follow health department guidelines to ensure they meet the minimum requirements, but most machines will exceed these, adding an extra margin for safety. Check the machine manual and settings to find out exactly what timing your particular machine follows, as you may have to comply with particular local government rules. The cycle takes about 2 hours and is usually set to be done overnight when the machine is not in use. This process means the machine only needs cleaning every 14 days, which is useful for high volume situations and where labour is short or at a premium.  Even though your machine may have one or both of the above features this does not mean that you can neglect basic hygiene procedures with your mix and machinery. Any pre-prepared mix needs to be stored at 4°C or less when outside the machine, and all other equipment, utensils and surfaces including nozzles, hopper lids and handles need to be cleaned down regularly (once a day at the least) with suitable food grade sanitiser. It also goes without saying that operators need to follow good personal hygiene practices, with hand washing and disposable gloves, clean aprons and hair covers where appropriate, and a full awareness of local government public health food handling requirements. Obviously the more features a machine has, the higher the cost of the machine, and the more complex it is to run. Machines with full pasteurisation cycles, a pump, and multiple barrels are technologically quite complicated and need to be treated with respect to avoid unnecessary maintenance issues and the costs associated with these. Allowing the material to run down in the barrel, adding too much water to the mix, and putting additional ingredients into the hopper can all upset the delicate balance between the mix and the machine. Soft serve mix is a reasonably sophisticated product which has been carefully formulated to ensure the machine runs at its optimum, so any changes you make need to be well thought out to protect your investment. Check with your soft serve supplier before being tempted to deviate from their recommended methods. In our next post How to Choose Part 5, we give some tips on how to get the most out of your machine. In following posts we will look at some common operational problems and provide some practical troubleshooting. In the meantime check out our previous posts: How to Choose Part 1 How to Choose Part 2 How to Choose Part 3

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

|

Wholefarm Australia Pty LtdOffice: Unit 3, 16 Veronica StreetCapalaba, QLD 4157, Australia. Postal: PO Box 5698, Alexandra Hills, Qld 4161, Australia. Phone No:+61 7 3824 4737 Email: [email protected] copyright Wholefarm Australia Pty Ltd 2023 all rights reserved |