We've said it before but we can't emphasise this enough - read your machine manual, then read it again. Then read it once more, and train your staff accordingly. Your machine is a finely tuned piece of equipment so you have to treat it with respect. We regularly get calls to say that a business is having problems with their machine and nine times out of ten it could have been easily avoided. Here are some of the common issues: A. The machine is on but the soft serve mix isn't coming out of the barrel. Solution:

B. The soft serve mix has frozen in the chamber. Stop the machine immediately and allow to thaw or you will damage your gear box and other parts. Solution:

C. The soft serve mix is coming out icy or yellow. Solution:

D. The machine is making a weird noise. Stop your machine immediately and troubleshoot. Reasons:

There's nothing nicer than a beautifully made soft serve, wishing you many happy servings!

0 Comments

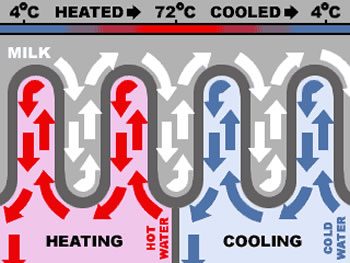

Tips to get the most out of your machine Don't let that investment go to waste! Check out our tips below for a smoother operator and customer experience. 1. Don't let the hopper run empty. This sounds elementary, but it is surprising how many operators don't top up the hopper with soft serve mix promptly when it gets low. Many machines have a warning beep that let you know it is time to restock, but these can become background noise and get ignored. By letting the mix become too low or run out, you run the risk of damaging your machine. What little is left in the barrel can freeze up, jam the blades and in the worst case scenario blow up the machine gearbox. This can then become a costly exercise to put right, but is easy to avoid with a little care and attention in the first place. 2. Make sure the breathing tube is inserted and working correctly (for gravity fed machines). If this is not placed correctly air can't combine with the mix at the proper ratios, and the mix may freeze resulting in damage to your machine. Make this one of your checks when starting for the day, and when topping up the hopper. 3. Make sure your machine is calibrated correctly. Many machines have settings that can be adjusted to suit the soft serve or frozen yoghurt mix you are using, e.g. you can raise or lower the freezing temperature a degree or two to reduce iciness or increase firmness, or increase/decrease the air intake. If these settings are wrong you can end up with a sub-standard soft serve ice cream that melts too quickly, freezes up in the machine, or you simply go through too much mix and don't meet your cost calculations. Talk to your machine supplier about how you can achieve the best settings for the product you want to create. 4. Keep your machine clean. It goes without saying that food hygiene should be at the front and centre of your operations. Soft serve mix will happily keep at fridge temperatures of 4 degrees C or less for several days, but after this your machine will need emptying and cleaning thoroughly before the next batch. As with any other food type, bacteria can get a foot hold in crevices and in areas such as behind gaskets and seals where food residue lurks, so follow your machine manufacturer's recommendations on using food grade cleaning products that will sanitise these areas and prevent contamination from occurring. Once you know how, it is a relatively simple procedure to remove the blade and other parts from the barrel, scrub and air dry these, and put it all back together ready for the next use. You happily do the dishes and wash down other areas in your food business, so look upon this as a similar essential exercise. 5. Know your machine. Read the manual, then read it again. Get to know your machine, what it can and can't do, and how it operates. You have bought an expensive piece of machinery and it will serve you well if you understand it and use it properly. If you are renting, the same applies - don't assume it is only your supplier's problem, because you are the one who will pay in lost sales if your machine is not operational. A small amount of time invested now will pay dividends later in lower maintenance costs, and less down time. It will also make it easier for you to train your staff and trouble shoot without having to continually call out for maintenance. 6. Ask for help. Don't be afraid to ask for help from your machine supplier, maintenance person or from the manufacturer. The sooner a problem is dealt with, the quicker you can go back to doing what you do best - making your customers happy! Our previous post, How to Choose Part 3, explored the difference between gravity fed and pump soft serve machines, and how these differences would affect your ability to provide what your particular operations require. Next we examine additional features that may be useful, or even mandatory in some instances. Chilled Hopper Machines Machines with hopper chilling capability have a setting that allows any left over material at the end of the day to remain in the hopper overnight instead of being drained and stored in the fridge. The hopper remains constantly chilled to around 4°C (standard fridge temperature). This allows any mixture to be safely left in the hopper for up to 5 days before it needs to be discarded and the machine cleaned. In practice most operations would have a continual throughput, with material only being left overnight, but you can see how useful this feature can be during slow periods, and how labour saving it can be.  Pasteurisation Cycle This is an automated feature where the machine performs a pasteurisation cycle overnight. Pasteurisation is a heat treating process that kills any pathogenic (disease causing) microorganisms in certain food groups. The material in the hopper and the barrel is heated to 71.7°C for 15 to 25 seconds, then cooled back down to 3-4 °C. Machine manufacturers follow health department guidelines to ensure they meet the minimum requirements, but most machines will exceed these, adding an extra margin for safety. Check the machine manual and settings to find out exactly what timing your particular machine follows, as you may have to comply with particular local government rules. The cycle takes about 2 hours and is usually set to be done overnight when the machine is not in use. This process means the machine only needs cleaning every 14 days, which is useful for high volume situations and where labour is short or at a premium.  Even though your machine may have one or both of the above features this does not mean that you can neglect basic hygiene procedures with your mix and machinery. Any pre-prepared mix needs to be stored at 4°C or less when outside the machine, and all other equipment, utensils and surfaces including nozzles, hopper lids and handles need to be cleaned down regularly (once a day at the least) with suitable food grade sanitiser. It also goes without saying that operators need to follow good personal hygiene practices, with hand washing and disposable gloves, clean aprons and hair covers where appropriate, and a full awareness of local government public health food handling requirements. Obviously the more features a machine has, the higher the cost of the machine, and the more complex it is to run. Machines with full pasteurisation cycles, a pump, and multiple barrels are technologically quite complicated and need to be treated with respect to avoid unnecessary maintenance issues and the costs associated with these. Allowing the material to run down in the barrel, adding too much water to the mix, and putting additional ingredients into the hopper can all upset the delicate balance between the mix and the machine. Soft serve mix is a reasonably sophisticated product which has been carefully formulated to ensure the machine runs at its optimum, so any changes you make need to be well thought out to protect your investment. Check with your soft serve supplier before being tempted to deviate from their recommended methods. In our next post How to Choose Part 5, we give some tips on how to get the most out of your machine. In following posts we will look at some common operational problems and provide some practical troubleshooting. In the meantime check out our previous posts: How to Choose Part 1 How to Choose Part 2 How to Choose Part 3 So you have looked at the market for your business, decided on the products you would like to sell, and are now checking out soft serve ice cream machines that will suit your operations. As mentioned in How to Choose Part 2, space will be one of the deciding factors. Do you have the luxury of space to add a free standing machine, or will a counter top suffice so you can have additional cupboards or shelving underneath for storage. Next we look at the two different types of soft serve machines available when it comes to feeding the mix from the hopper into the freezing chamber.  2. Gravity Fed versus Pump (Pressure-Fed) A gravity fed machine is exactly that - the mix goes into the hopper at the top and falls by force of gravity into the cooling chamber that produces the freezing effect. These types of machines are less complicated to set up and maintain as they have less working processes. As long as there is a clear passage from hopper down to the barrel where the soft serve ice cream mix is frozen, things should run relatively smoothly. You will need to keep your hopper mix topped up to provide some weight for this operation. You also need to check for blockages regularly and make sure the breathing tubes are correctly fitted (these allow air to be combined into the mix to create that fluffy effect). Because these machines rely on gravity the mix can take time to get to the barrel cooler and freeze to temperature. This can be a problem when you want to produce a larger number of soft serves quickly, as the machine may not be able to keep up using the force of gravity alone and you will have to wait for a short period for it to catch up.  Pressure-fed, or pump machines, employ a pump to bring the soft serve ice cream mix into the chamber at a regular rate. With extra working parts these are more complicated to work with and also more expensive to buy. They do, however, allow for greater overrun. This is the amount of air that can be combined with the mix to create a light, soft and fluffy soft serve ice cream. Good overrun percentages are around 40-45%. This means that less actual mix is used per serving which is more cost effective for the business. Overrun can be adjusted depending on the type of machine you have, and a good technician will be able to help with machine settings so you get the optimal efficiencies from your unit in terms of both air flow, temperature settings and general running. Pump machines also have greater production capacity so are often used in high volume settings where there are greater numbers of serves per hour. If your business is in the position where you do not have the luxury of waiting for the machine to catch up to your production requirements, then this is the type of unit for you. As always it comes down to budget, so you may opt for a second hand soft serve machine rather than buying new if you require one of the more expensive types. This then gives you time to see if the unit suits your business model, and to check that you will actually get the sales you are hoping for. see also: Soft Serve Machine: How to Choose - Part 1 Soft Serve Machine: How to Choose - Part 2 Soft Serve Machine: How to Choose - Part 4 As mentioned in our post How to Choose Part 1, the type of soft serve ice cream machine you need will partly depend on the products you want to sell, and the customer base you have. It is important to understand the difference between soft serve ice cream and standard 'hard' ice cream before you make your choice. Soft serve ice cream is typically served at a higher temperature (generally around -4°C), whereas standard ice cream is held at -15°C during storage. This is why soft serve ice cream cannot usually be put back into a freezer once manufactured, unless it has been specially formulated to do so. The lower temperatures involved cause ice crystals to form in the mix which makes the soft serve taste icy and feel rough. A good quality soft serve should be creamy smooth yet firm, with no hint of iciness. It is worth noting that our Goldenfarm and Yomaxx soft serve formulas can be used to create hard ice-cream. These have been formulated to be frozen with just a small adjustment to the recipe, and no loss of quality, so they can greatly increase the utility of your soft serve machine. There are a number of factors to decide when choosing the right machine for your operations, and these are explained in more detail over the course of the next few posts.  1. Counter Top versus Floor Standing Counter tops generally take up less space, with some great compact models available. They are usually cheaper so are a good choice for start ups and smaller enterprises with limited space. That said, all soft serve machines need a compressor, hopper and barrel, so even a small machine is going to take up a bit of room, so check the dimensions carefully to be sure it will fit where you want it to go before you commit your dollars to a purchase. Many counter top models only have the one barrel, which means you can only do one flavour at a time. This is not necessarily a problem, as you can change the flavour profile of your product by adding syrups when serving, using a mixer to produce flurries with added flavouring, or offering floats and thickshakes in a similar manner. You could also do a 'flavour of the day' to create interest, but bear in mind that to fully utilise your machine you really want the best selling and most versatile product in there at all times. This will typically be a vanilla that you can add flavours to post serve, but this does depend on your customer base so it pays to do your research. These types of machine may also have a smaller capacity per hour (e.g. some may produce 5 serves then require a minute or two to cool the mix back down or the product will become a bit runny). This is a concern when you have customers queuing out the door continually, but maybe not so problematic when trade is more steady and balanced out with other product offerings. If you really need more than one barrel be prepared to pay quite a bit more for a counter top model.  The floor standing machines are generally larger, but can also offer more barrels and larger capacity, which not only gives you the option of running different flavours at the same time, but also gives a greater serving rate per hour, which may be more important to your business in a high volume setting. They are also generally easier to move around into place, unless you keep your counter top model on a moveable trolley. Both model types require ventilation space to help with cooling (unless you have a water-cooled type of machine - more about this later). The manufacturer will tell you what the minimum gap should be but be sure to factor this into your space equations. If your area is well air-conditioned and/or ventilated this will help the machine's performance. A poorly ventilated, hot and humid space will limit the machine's efficiency and use more electricity in the long run.  A Soft Serve Machine is a relatively expensive piece of equipment, so you need to do your research before making (what is for most enterprises) a reasonable investment in the business. Before you start your research ask yourself a few questions about your business. 1. Who is my target market? If you are an existing outlet you will already know who comes through your doors, or who walks past them. Is there a lot of foot traffic, can you entice more people into your shop with some different offerings? Will you sell online or takeaway orders? Is there potential for impulse buys and are there certain days of the week that are better than others? Children tend to have different tastes to adults and you may need to be able to adapt quickly to move to the more in demand products, or respond to particular trends as they occur. 2. Which products do I actually want to sell on my menu? This may be straight out soft serve ice cream in a cone, or you may want to sell sundaes, parfaits, thick shakes, ice cream for dessert toppings, or some specialty items. The more products you can get from your ice cream machine, the more use and hence sales you will get from it, which will reduce your pay back period and increase your profits. It will also generate interest in your business and create more opportunities for social media marketing. 3. Is there something I can do to utilise the down time of my machine to make and sell more product? This could include buying mix that is also able to be made into a hard ice cream, so you can create your own 'factory' and sell pots. Some plain base mixes are good for adding flavours to so you can create your own specialty range. Other bases have a strong vanilla note that can work against flavourings, so trial and error is the key here. Don't discount frozen yoghurt mix either, this works extremely well with fruit and floral flavours. Not many soft serve ice cream products can be used for hard ice cream production because of the different freezing temperatures between the two types. However, the Wholefarm Goldenfarm and Yomaxx ranges are particularly suitable for this type of application, with only a few simple adjustments required. 4. Can I synergise with other businesses in my immediate area? There may be outlets nearby who offer savoury courses but not desserts. Entertainment venues such as cinemas, sporting venues, clubs and theatres may empty out at certain times. Can you take advantage of the extra foot traffic and need by having product ready to go at those times of the day, or working with these venues to deliver? Consider positioning your machine at a counter open to the street so you can continue to sell even when your main business has closed for the day. click here for Part two of How to Choose  What is the difference between a Parfait and a Sundae? Parfait is a French word meaning ‘perfect’ in English. Traditionally it is a dessert made from eggs, sugar, syrup and cream . These are heated up together and whipped to create a custard-like consistency, that is then flavoured with fruit or other ingredients, and frozen. Parfait is often frozen into moulds and served as slices, cubes or in individual containers to create beautiful shapes when it is turned out onto a serving platter. The meaning has expanded over the years to include other types of desserts that contain cream, ice cream or mousse. These are generally layered with ingredients such as jelly, cake, fruit and toppings, and served in a tall glass. This is where they can become confused with Sundaes, as the presentation can often look the same. A true parfait will contain eggs and will have been subjected to some kind of cooking process, whereas a Sundae generally has either soft serve or hard ice cream as its main ingredient, together with some syrup and topping. Another version of the Parfait uses ricotta as its main ingredient, which is then blended with sugar, cream and water, and frozen. This recipe doesn’t require a cooking process and is a quick and simple way to create a special but very tasty treat.  As for the Sundae, there are a number of versions of how it came to get the name. Some claim it was invented by a Mr. Sonntag from Illinois in 1890 who named the dish after himself (Sonntag means “Sunday” in German). Others claim that it is a variant of the ice cream soda that was banned from sale on Sundays in the 1890’s in Illinois because it was too showy. The soda was taken out and just the ice cream and syrup was sold, along with a name change that was slightly different from the traditional Sunday sabbath name so it wouldn’t be confused. Yet another version claims that this treat was sold back in 1890 in Wisconsin but only on Sundays. The spelling apparently was changed when a glass salesman ordered canoe-shaped dishes. What is certain is that Sundaes and Parfaits have been around a long time, and their popularity (apart from their wonderful taste) is partly due to the sheer amount of creative flavours and toppings available, which means there is something to suit everyone. Soft serve ice cream is a particularly good way to create a memorable Parfait experience for customers in a commercial setting because it can be flavoured and coloured easily, and is lighter than hard ice cream. This means it works well with layering of ingredients and makes it easier to eat. So whether you choose a Sundae or Parfait this summer, you can be sure you are tasting a little bit of history and a experiencing a little bit of heaven at the same time. Desert-tech is a fast growing market, with plenty of new ideas trending as well as some wonderfully creative and already established offerings. Some of the enticing options for you to choose from include ice-cream innovation (such as charcoal soft serve or nitrogen cooled product made right in front of you), and intelligent ovens that speed up the cookie-making process to give you the perfect bite every time. The availability of these delicacies means you can indulge, not just on special occasions, but anytime you want, from the creamiest variation of a soft serve ice cream or an ingenious Panna Cotta Mix, to vegetarian and vegan treats. Here are the three best options trending right now:-

You can't see them, but they are quietly working away, doing you a lot of good. Probiotics is the general term for bacteria, yeasts and other microorganisms that are beneficial to gut and general health. Our bodies contain trillions of bacteria of over 500 different species. Bacteria in our gut help to keep harmful microorganisms (known as pathogens) under control, assist with digestion and absorption of nutrients, and aid the immune system. Different strains of bacteria perform varying functions, e.g. some will aid in the fight against Crohn's disease, some work against digestive tract ulcers, and others help with the treatment and prevention of diarrhea, urinary tract infections and bladder cancer (Harvard Health Publishing, 2005). Taking probiotics on a regular basis can rebalance the body's natural gut flora, particularly after a course of antibiotics which can wreak havoc on the 'good' bacteria in the gut and cause digestive upsets as a result. Look for product labels which tell you the specific strains used, and what the live count is, then you can do your own research into the beneficial effects of each type. In today's COVID environment it makes good sense to take steps to boost your immune system and take charge of your overall health and wellbeing. Probiotic-containing foods are an excellent way of ensuring this happens. These kinds of foods include kombucha, kimchi, yoghurts and other types of cultured milk, sauerkraut, miso, some types of sourdough bread, and any other live fermented food. It is also important to 'feed' these good bacteria with the right kind of diet, which is why processed foods high in carbohydrates and low in fibre are frowned upon. They lead to poor gut health, lift blood sugar, and encourage the wrong types of gut flora. Instead, try adding extra fruit and vegetables to your diet, including blueberries, apples, chickpeas, lentils and almonds. Eating a wide range of proven health food choices is the best way to keep your gut in tip top condition, your weight in check, and a spring in your step. 29/4/2020 0 Comments In Lockdown You Make the Rules ... ... no problem, I'll just have it for lunch instead.

See our yummy range of soft serve and frozen yoghurt products to beat the lockdown blues. |

|

Wholefarm Australia Pty LtdOffice: Unit 3, 16 Veronica StreetCapalaba, QLD 4157, Australia. Postal: PO Box 5698, Alexandra Hills, Qld 4161, Australia. Phone No:+61 7 3824 4737 Email: sales@wholefarm.com.au copyright Wholefarm Australia Pty Ltd 2023 all rights reserved |